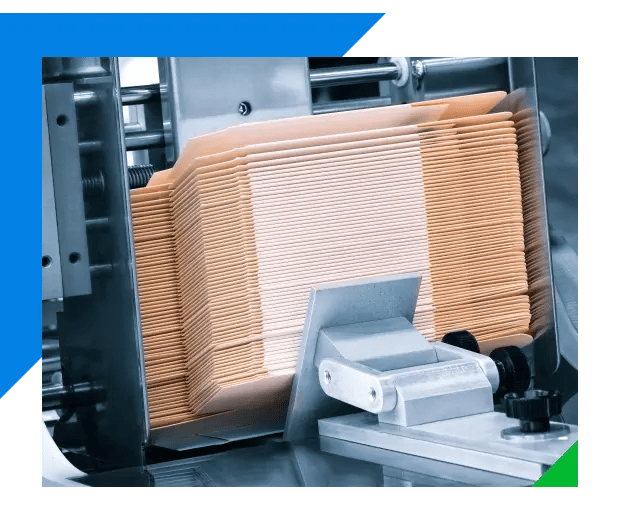

Trillora acts as your full-service packaging department.

That means we produce custom designs tailored to your unique products and needs. We handle local packaging suppliers and interact with your factories. And we conduct quality and performance testing on your packaging.

For brands, this lessens headaches and can result in waste reduction, greater efficiencies, more sustainability, and net savings too.