“How much does packaging cost?” is the wrong question to ask.

Instead, ask: “How much does it cost to use packaging?”

To find the answer, you must consider how packaging impacts and interacts with your entire supply chain.

You know how much you spend on boxes and materials, but your packaging choices could be costing you far more than you think. Failing to optimize designs for freight efficiency and product protection inflates the cost of every shipment, and can harm brand reputation too.

“How much does packaging cost?” is the wrong question to ask.

Instead, ask: “How much does it cost to use packaging?”

To find the answer, you must consider how packaging impacts and interacts with your entire supply chain.

Optimized packaging has positive ripple effects across a business. Using standardized materials with the right specifications, ensuring items are protected but not overpacked, and designing for maximum cube density have produced significant savings and benefits for Trillora customers. Here are a few examples of our outcomes:

Improvement in shipping efficiency

This client was able to take 2,000 trucks off the road as a result.

Improvement in pallet utilization

This backpack and outdoor gear maker can now fit 16 cases of its product on each pallet, up from 12 previously.

Reduction in total costs

The global footwear producer’s savings came in year one, paired with improved packaging quality & consistency.

Optimizing your packaging program can feel overwhelming. It doesn’t need to be.

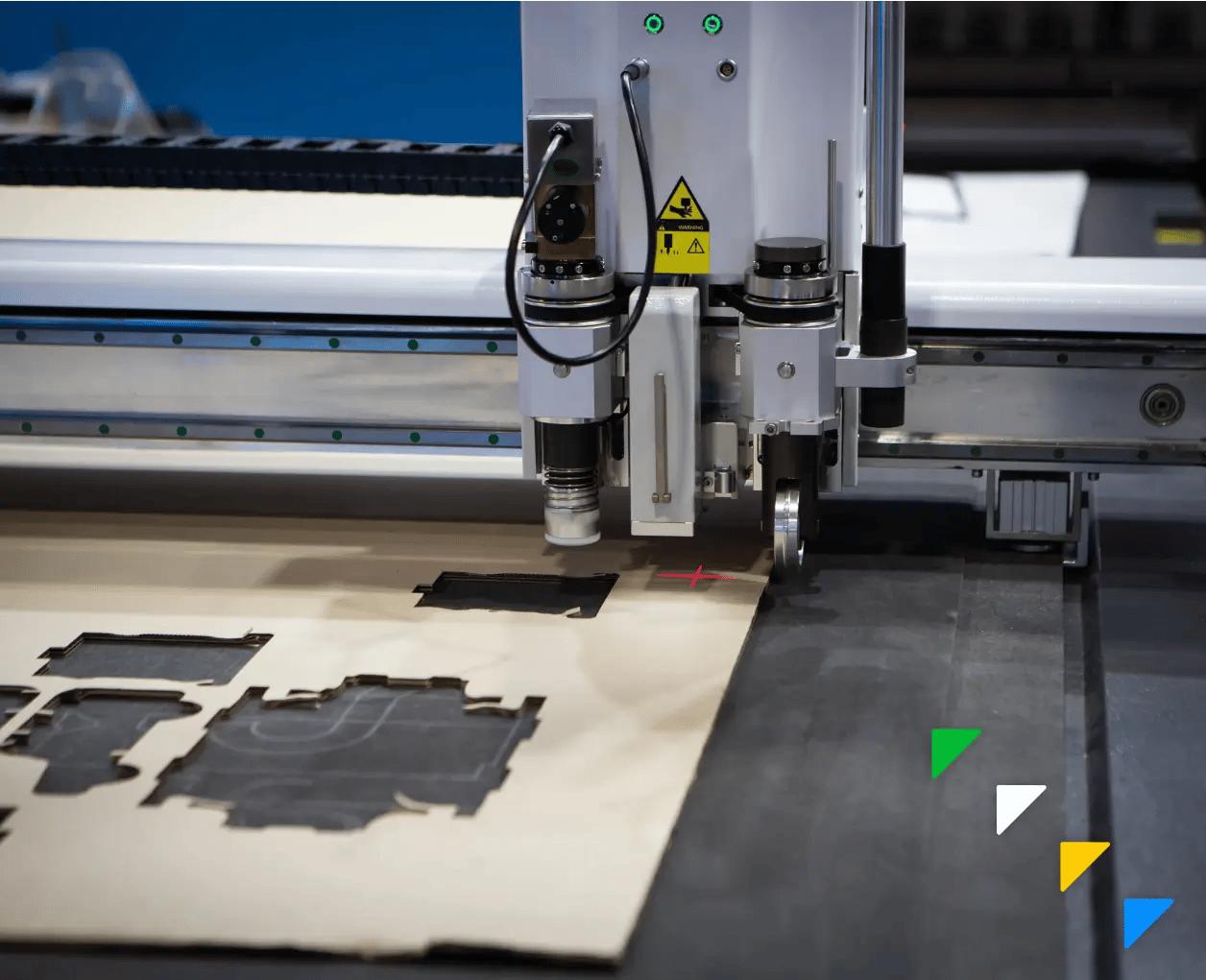

A packaging audit is a critical first step that lays the foundation for changes to come. Performed by Trillora’s packaging design and supply chain experts, our audit uncovers what savings and opportunities lie hidden in your supply chain.

Is your packaging designed for distribution? Are you getting what you paid for from your packaging supplier? An audit will answer these questions and many more.

Freight isn’t cheap. While packaging must be designed for efficiency and protection, overpacking often provides no real benefit. Are you shipping too much air?

Optimization isn’t just about packaging design. The distribution center is a key focal point when overhauling a packaging program. Explore how Trillora approaches DC efficiency here.

Trillora’s team functions as a full-service packaging department for brands, from design to production to delivery. Our services and expertise include:

Well-designed packaging isn’t worth much if the final product doesn’t consistently meet quality requirements. This can be a particular challenge for brands that use factories across different countries and regions.

Trillora’s vast supplier network and ongoing quality monitoring ensures the packaging that we design for you is produced properly, no matter the geography. It's all part of how Trillora manages packaging programs to help brands streamline their operations uncover hidden savings in their supply chains.

Optimizing your packaging program requires taking control of the process and discovering savings throughout the supply chain.

Our ebook gives an overview of the most important steps for creating a packaging program that minimizes waste and inefficiencies, while maximizing value for stakeholders and end-users. Click below to learn more.